The windshield of the Potez 58 is a bit tortuous to put in place with a very curved frame and many rivets to reproduce

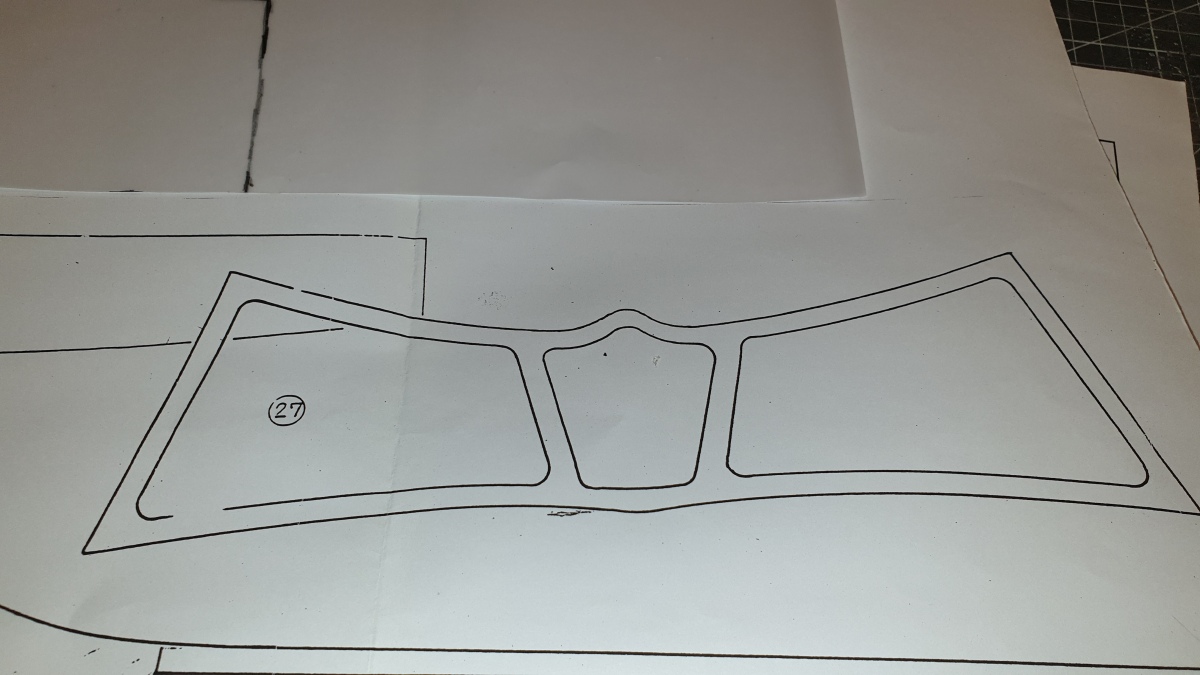

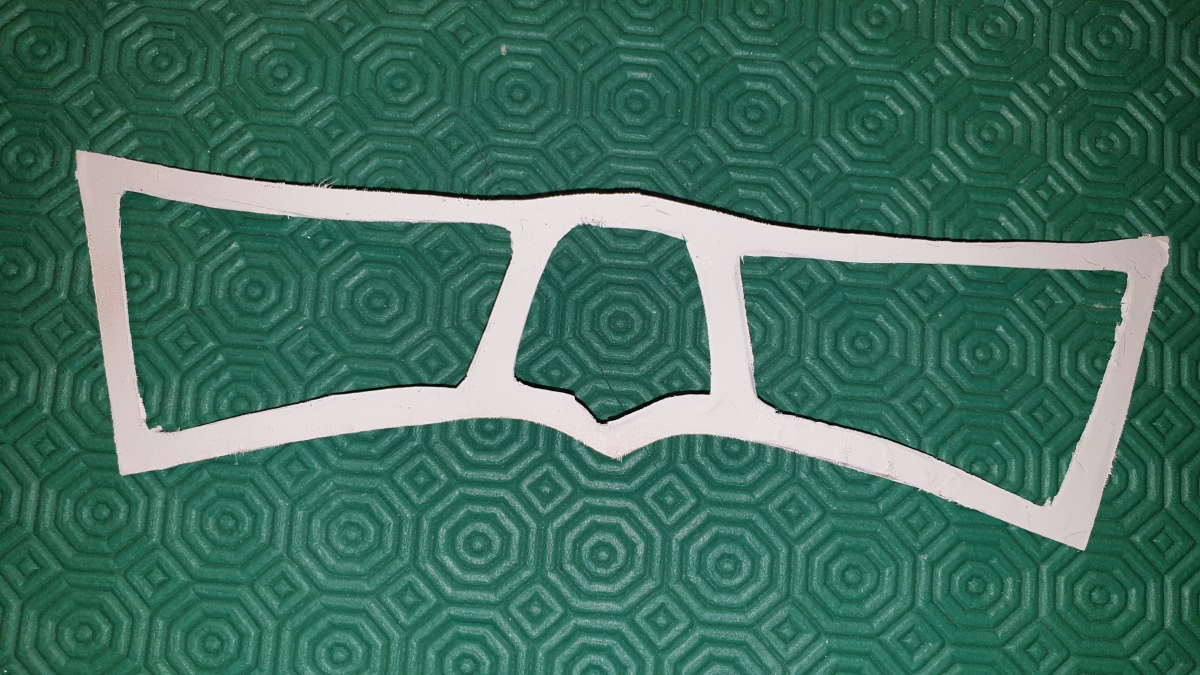

To make it, I cut the frame in 5/10 plywood. After soaking it in water, I presented it on the fuselage to find the fit. I had to do three before I had a correct one. Indeed, it was not easy to predict the right shape flat from the image.

I then covered with a layer of nitrocellulose coating and fiberglass at 25g / m².

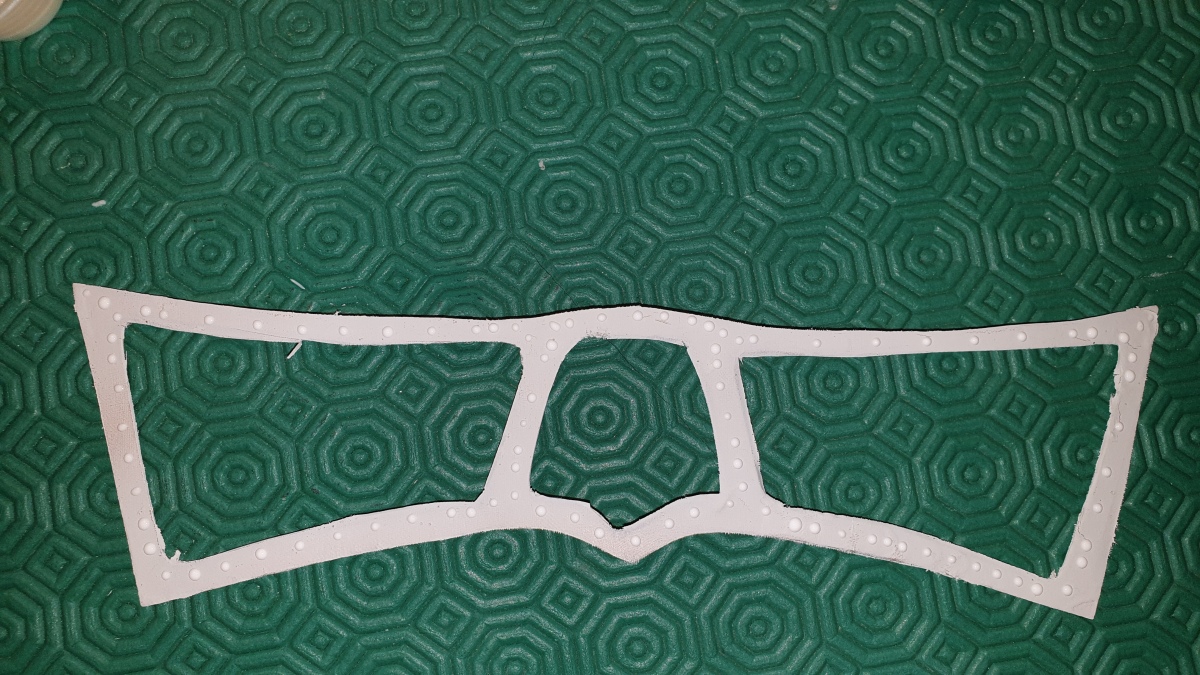

Then, I covered with a filling coating before depositing the drops of glue to reproduce the rivets

The bonding stage is delicate, but went well. There are still parts to fill between the windshield frame and the front formwork.

To fill in the gaps, I used balsa, balsa lite and nitrocellulose putty. A real work of patience.